Challenge

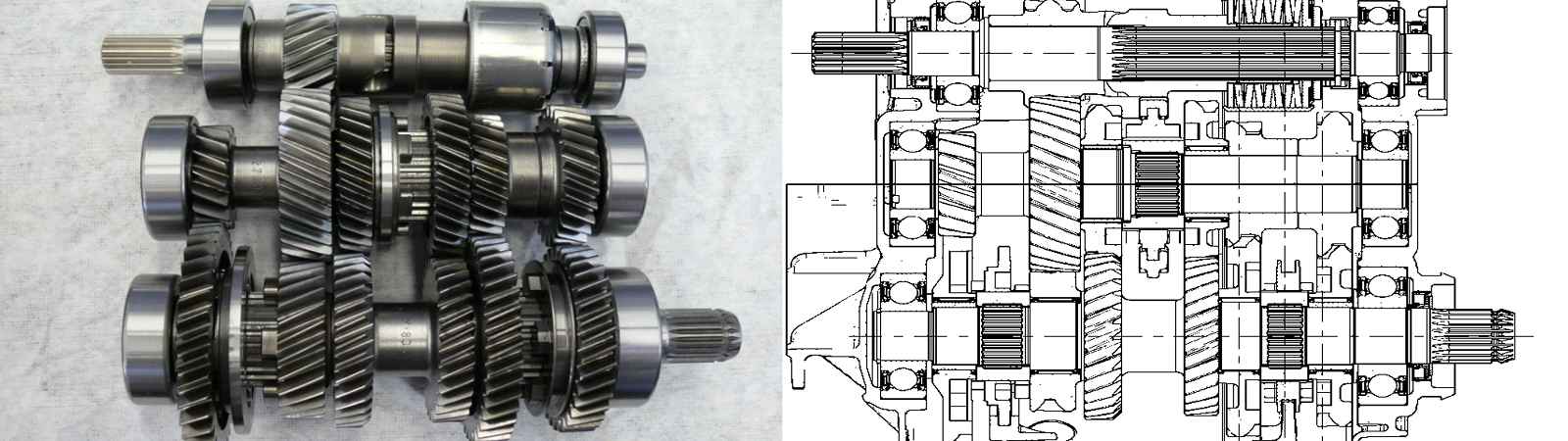

In this project, the shifting process of a motorcycle transmission was recorded and evaluated without certain problems regarding shiftability being defined in the foreground. The customer’s request was to measure the shifting processes, to create a multi-body simulation model and to validate it with the measurement data from tests. At the beginning of the multi-body simulation, it was to be determined whether there was potential for optimizing the switching process.

Оbjective

To assess the shiftability of the gearbox and optimise the shift operations and to carry out virtual tests (shift scenarios) by varying different shift parameters in order to develop a new type of gearbox.

Solution

- Concept

- Adaptation and experiment

- Multi-body simulation

- Optimization of the shifting process

Result

With the help of multi-body simulation and the simulation of different switching scenarios, the claw geometry could be optimized. As a result, the improvement of the switching process could be implemented. In addition, the simulation models created and the measurement data from the tests were used for the further development of a gearbox type. This saved a lot of development time and costs.

We help development managers from the construction, agricultural and forestry machinery sectors as well as the automotive industry to avoid capacity bottlenecks in the development of drivelines and axle systems and to significantly reduce development times.